ProDesk-3D

Led by AM-COE in collaboration with University of Nottingham, CTU Prague, MetLase, OpTek Systems, Attenborough Medical, SolidVision, and ECHOTools.

Consortium funded by Innovate UK | Part of Horizon Europe | Evaluated by SMART Eureka

A hybrid, multi-process solution integrating additive manufacturing, precision micro-machining, laser processing, polishing, advanced automation, and in-situ inspection, enabling flexible, sustainable, and high-precision end-to-end production of complex micro-components across medical, aerospace, electronics, automotive, and research-driven industries.

What is ProDesk-3D?

Self-Sufficient Desktop Machine

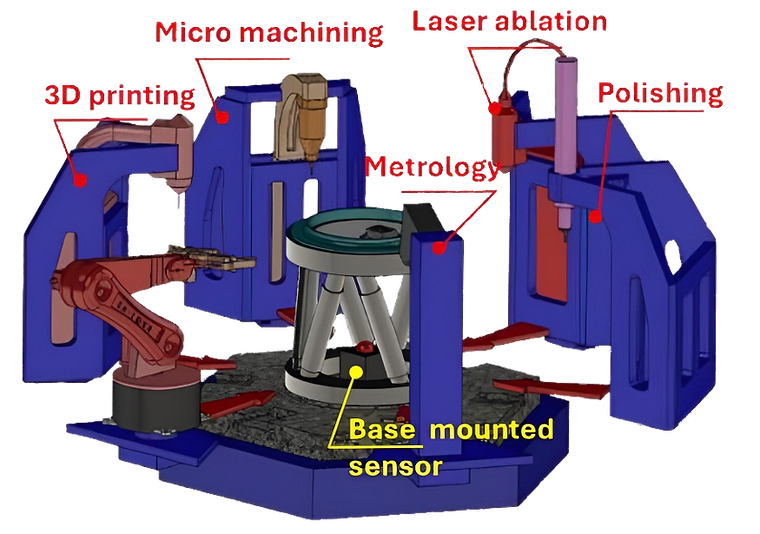

ProDesk-3D is a compact, reconfigurable desktop machine that integrates additive, subtractive, and finishing processes with advanced multi-axis positioning. By combining slot-in modules, a hybrid 6+2 DoF platform, smart robotics, and in-situ inspection, ProDesk-3D enables the high-precision production of 3D micro-components with minimal human intervention. ProDesk-3D works layer by layer to machine internal features and hidden sections, providing a larger degree of product design freedom. The system targets applications in medical, aerospace, electronics, and automotive industries

Key Features

Reconfigurable Slot-in Modules

Modular units for extrusion, CNC, laser, and finishing tailored to each job.

Hybrid 6+2 DoF Kinematic Platform

Combines a 6-axis hexapod with two extra pie-motor axes for precise multi-axis machining and seamless part transfer between modules.

In-Situ Metrology & Machine Vision

Real-time defect detection and correction to ensure accuracy and reduce waste.

Compact & Sustainable

Small footprint and energy-efficient. Designed to cut material and factory costs.

Automated Operation

Smart robotics and control systems reduce manual handling transfer error, and human error.

Layer-by-Layer Machining

Each layer is machined as it is printed, enabling rapid error correction and access to internal features for greater design freedom. This improves part quality and opens applications in medical implants, aerospace cooling structures, and advanced electronics.

Targets

75%

less material waste from modular, right-sized design

40%

longer machine lifespan vs. single-process tools

0.5

μm inspection precision from integrated in-situ metrology

70%

reduction in energy use

30%

fewer rejected parts through real-time defect detection

5

interchangeable processing modules (extrusion, CNC, laser, polishing, inspection)

50%

smaller factory footprint

±100

μm positioning accuracy with hybrid 6+2 DoF kinematic platform

4 in 1

replaces 4+ conventional machines

Potential Applications

ProDesk-3D’s hybrid approach enables the production of high-precision, customized micro-parts across a wide range of industries. Its ability to combine complex geometries with fine surface finishes opens new possibilities for innovation and cost-effective manufacturing.

Medical Devices & Implants

Patient specific orthopedic implants, surgical tools, customized prosthetics, exoskeletons with integrated actuators

Aerospace Components

Turbine blade micro-structured cooling channels, micro-truss and micro-lattice structured components

.png)

Micro-electronics & Semiconductors

MEMS sensors and actuators, micro-coolers, heat sinks, interposers and micro-interconnects for 3D chip packaging

Our Partners

ProDesk-3D project has received funding from INNOVATE UK and MEYS through Eureka and the Clusters programme and SMART Cluster.

.png)